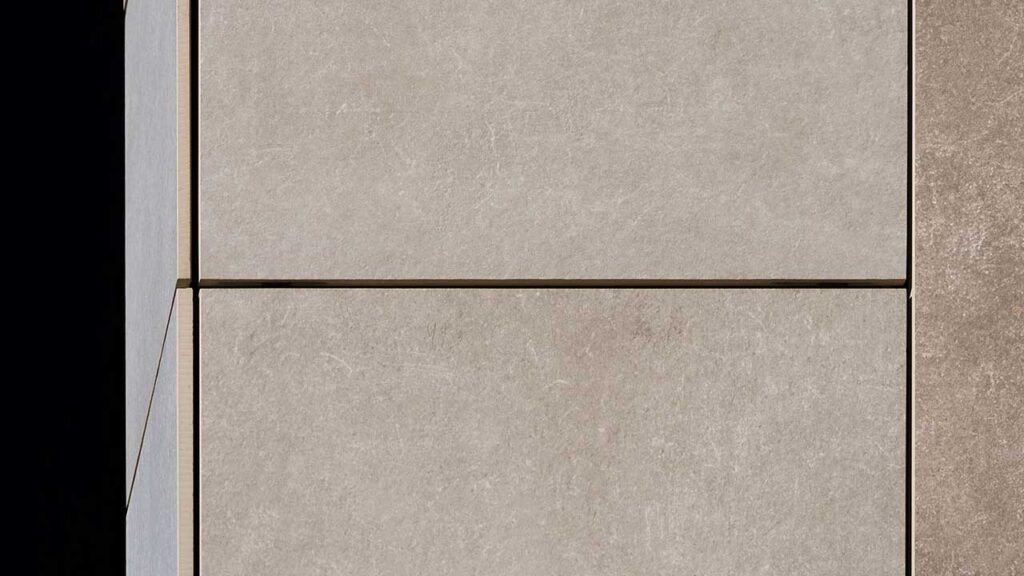

Porcelain cladding is an effective way to achieve a crisp, clean look on a building’s external appearance. As a result, it’s becoming hugely popular, with many manufacturers springing up.

But how much do you know about it?

To help you wade through your design decision-making process, we’ve developed a Design Guide to give you a step-by-step system. To help you design the most cost-effective open-joint porcelain façade for your building projects.

As a quick overview, the ten steps include the following.

The Cladding

- What are your cladding panel sizes?

- Color-body or through-body porcelain?

- What color and finish does your design need?

- Do you want exposed or concealed fasteners?

The Substructure

- What are your building’s design pressures?

- What’s your build-up requirement?

- What’s the pattern for your panels?

Your Application & Use

- What’s your waste-to-yield factor?

- Do you want field-cut panels or pre-cut from the factory?

- Does your design require window returns?

Today’s newsletter looks at the first four critical questions about your project’s cladding and considerations you need to ask and answer before choosing the proper porcelain cladding for your project. And to make sure it fits within your client’s budget.

1) What are your cladding panel sizes?

We produce exterior porcelain cladding panels with standard pre-set molds in various sizes (i.e., 6’x2’, 4’x4’, 4’x2’, etc.). Selecting these standard mold sizes is your more economical choice because we’re using the industry’s standard technology. Cost Impact: $

Another tip to keep your costs down and get other sizes is to choose a size that cuts down these standard mold sizes in halves or thirds.

However, if your design requires it, slab-size porcelain can be produced in a large format as a raw sheet. And you can cut that sheet down to multiple custom panel sizes. This customization does come at a premium cost because we’re using the latest “continuous press” cutting technology to produce your porcelain cladding. So, you’ll want to keep that in mind and look for other cost-saving opportunities in the panel design options. Cost Impact: $$$

2) Color-body or Through-body?

We produce exterior porcelain cladding panels with standard pre-set molds in various sizes (i.e., 6’x2’, 4’x4’, 4’x2’, etc.). Selecting these standard mold sizes is your more economical choice because we’re using the industry’s standard technology. Cost Impact: $

Another tip to keep your costs down and get other sizes is to choose a size that cuts down these standard mold sizes in halves or thirds.

However, if your design requires it, slab-size porcelain can be produced in a large format as a raw sheet. And you can cut that sheet down to multiple custom panel sizes. This customization does come at a premium cost because we’re using the latest “continuous press” cutting technology to produce your porcelain cladding. So, you’ll want to keep that in mind and look for other cost-saving opportunities in the panel design options. Cost Impact: $$$

3) What color does your design need?

As you start choosing the right color for your cladding panels, you’ll need to know how many square feet of your façade is porcelain cladding. Knowing this will help you quickly determine which colors and finishes are available for your project.

Active Stock Production (Readily-available):

Does your façade use less than 15,000** square feet of raw porcelain material? If so, you can select from our active stock of colors within specific panel sizes.

With so many possible color and finish combinations for your porcelain cladding design, having them all readily available for any project size would be a little crazy-making. And unsustainable.

Here’s how to choose your active stock porcelain color:

- Go to the Porcelanosa Facades website: www.porcelanosafacades.com

- Select the “colors” menu, which takes you to our collection of colors.

- Filter by “Active Stock” Items.

- You can also download the current Active Stock Catalog PDF document from the resources tab.

Special Production (Choose your porcelain and size):

If your façade design uses over 15,000** square feet of raw porcelain material, you have two more options to consider.

The first option is our Special Production. You can choose between the many existing colors in our catalog. And we’ll form it into the mold size that best suits your façade while maximizing and meeting your budget.

And remember, “special production” doesn’t mean “more expensive.”

We simply take an existing finish “recipe” and put it in a standard, pre-set mold size we already have. This optimizes your exterior facade design intent.

Hit “Reply” and ask us about our Design Assist service. We’ll partner with you to develop a cladding system that fits your design intent and budget.

Custom Production (Your unique design):

This final option is our “Design Your Porcelain” Program.

You can read more details about this program on page 32 of our catalog

We’ll help you design your own unique, signature façade panels. If this sounds like what you’re looking for on your next project, be sure to check out our program.

Take your building’s exterior facade design to the next level by designing your unique cladding material.

(**Please Note: With an average waste factor of 15%, if your façade’s net area of exterior porcelain cladding is 13,000 SF, it will use 15,000 SF of raw material. And, as we said above, we’re happy to help you figure this part out.)

Once you’ve figured out your color and finish, ask yourself…

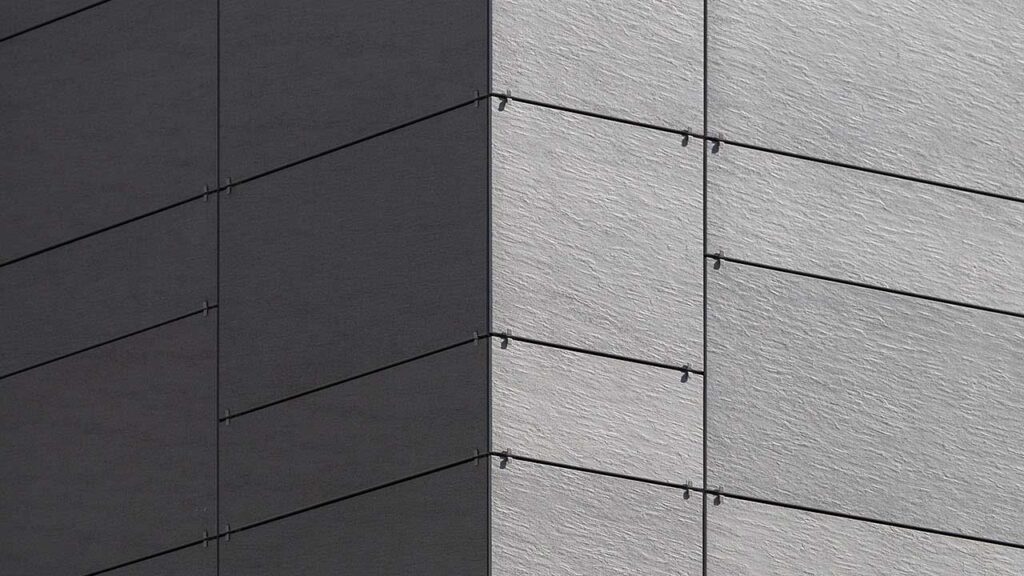

4) Do you want exposed or concealed fasteners?

You’ll find most cladding materials offer either exposed or concealed fastener options. And, when asked, most architects choose concealed fasteners for the cleaner look for their façade.

However, it’s well worth considering the cost impacts of each fastener type to keep your façade materials within the project’s budget. Below are the fastener options to consider for your panel size category (review step 1 above):

If you have standard size porcelain panels, you can choose from the following:

- Exposed fasteners; Cost Impact: $

- Concealed fasteners with kerfs; Cost Impact: $$

If you have large-slab size porcelain panels, you can choose from:

- Exposed rivet fasteners; Cost Impact: $

- Concealed undercut anchors; Cost Impact: $$$

More critical questions to ask …

This article covers just four of the questions we use as a design guide to help you achieve your vision and make it possible. As you can see, each decision you make along the way here impacts your façade costs. But knowing how each factor can affect your expenses will help you control those costs and tweak the system to meet your budget.

In the next newsletter, we’ll look below the surface and explore your options for the substructure.

Can’t wait? Reach out, and we can help you find the cladding system that will help you stay on budget and keep your design vision intact.

Until next time, keep growing your garden with beautiful building facades…

Thank you,

Your Partners in Design at

1) Sign up for our Virtual Online Lunch & Learn CEU presentation.

Sign up here for our presentation called, “Ventilated Façade System for Buildings.”

You’ll earn 1 AIA HSW CEU, and you’ll learn more about when & how to use a ventilated façade, as well as the advantages you’ll get using a ventilated façade over using other cladding systems.

SIGN UP TODAY!

2) Contact us for a free, no-obligation project consultation.

Go here to schedule a no-obligation call. Get to know us and share your vision for your project. If this project isn’t a great fit, we’ll just let each other know. And part as new BFFs looking forward to the next chance to work together.

SIGN UP Or you can always give us a call at 201-712-0556 (x2218)!

3) See if your project is a good fit for our Design Assist service.

Check out our two-page Design Assist Services description here to help understand a bit more about this awesome way we can work together.

The TL;DR version: If your project meets just two simple requirements, our complimentary Design Assist service will help ensure your façade design’s success, while saving your design team time, money, and headaches.

Check it out today!